how tin ore is process

tin ore process

Tin Ore Mining Process Xinhai. The density of tin ore is larger than the paragenetic mineral, so the mining process of tin ore apply gravity separation.

the process of mining tin ore gartenbau .

the process of mining tin ore aiipsin the process of mining tin ore Tin opportunities in QueenslandDepartment of Natural, min During the next decade . [Send Message] Tin Ore Mining Process comtechgroupin. Tin Ore Mining Process ccsindiain Tin is a chemical element with the symbol Sn (for Latin: stannum) and atomic number 50, is a post .

What Is The Process Of Processing Tin From Its .

what is the process of processing tin from its ore. what is the process of processing tin from its ore. How tin is made material used processing steps ...

do you process tin ore .

Tin Element information, properties and uses | Periodic ... Tin is found principally in the ore cassiterite (tin ... tin foil is made from aluminium and ...

ConflictFree Tin Initiative | Process

This project started in a tin ore (cassiterite) mine in South Kivu and built on two supply chain systems: the ITRI Tin Supply Chain Initiative "iTSCi" – an upstream traceability and due diligence mechanism – and the ConflictFree Smelter (CFS) program.

Tin | The Tekkit Classic Wiki | FANDOM powered .

Tin is the product of smelted Tin Ore or Tin Dust. It is a metal used in the creation of Tin Cans, RE Batteries, Fuel Cans, BatPacks, Empty Cells, and Tin Cables. It can also be used as a cheap alternative to Iron Ingots to craft Buckets. Tin .

GCSE CHEMISTRY Extraction of Metals What .

Metal ore deposits are a finite resource (there are only a certain amount of them) and nonrenewable (once used, they are gone and will not be replaced). Many metals are obtained today from recycling (melting and refining) scrap metals. About half of the aluminium, copper, lead, steel and tin that is used in the UK come from recycled scrap metal.

the process of mining tin ore .

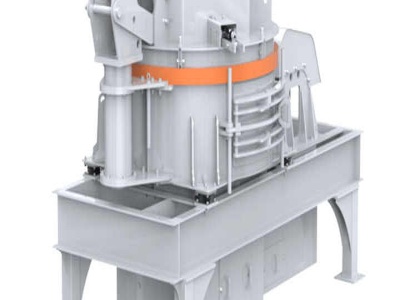

Tin Ore Mining Process Diagram Stone Crushing Machine. Tin Ore Mining Process Diagram. Tin Crusher,Tin Ore Grinder, ... Tin ore processing plant for tin mining process. Tin Ore beneficiation process Methods.

Uranium Mining and Extraction from Ore – .

The chemistry of these processes is very similar to the extraction methods, except that the leaching solution is pumped into the uranium ore while it is still in the ground. [2,5] Fig. 3 shows a schematic of the insitu leaching process, in which the leaching solution is pumped into the ore zone containing the uranium ore.

tin ore refine process

tin ore refine process tin mines equipment china tin ore mining procedures tin mining in tanzania tin flotation process tin mining in burma tin ore ...

Methodology and specifications guide Iron ore Platts

Methodology and specifications guide Iron ore ... assessment process to assess the value of iron ore. The MOC assessment process establishes core standards ...

tin ore mining process mining .

Tin Ore Mining Process Diagram . Tin Crusher,Tin Ore Grinder,Tin Ore Processing,Tin Mining ProcessTin Mining Process. Much at socalled helip. more>> Dartmoor tinmining from Dartmoor tinmining The wheelpit at Huntingdon mine. The At first this process operated on the dry ore,which was shovelled in and removed by .

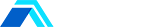

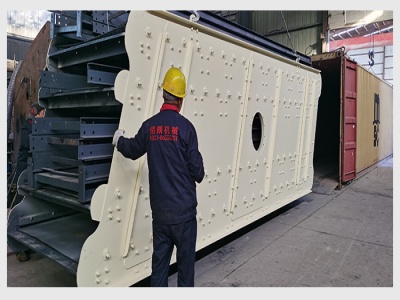

Tin Ore Mining Process

The density of tin ore is larger than the paragenetic mineral, so the mining process of tin ore apply gravity separation. However, all kinds of Iron oxides ...

Tin

The most important ore mineral of tin, ... window glass is made by pouring molten glass onto molten tin; this process results in flat sheets of glass.

Copper Mining and Extraction Sulfide Ores

Copper Mining and Extraction: Sulfide Ores. ... An ore is a rock or ... About 200 years ago the UK was an important world source of copper and tin and ...

GCSE CHEMISTRY Extraction of Metals What .

What is a Metal Ore? A solid element or compound which occurs naturally ..., lead, steel and tin that is used in the UK come from recycled scrap metal.

Tin Ore Beneficiation Process

The density of tin ore is bigger than paragenetic mineral, ... Tin ore separation process. ... Gold CIL process. Lithium ore Beneficiation. tin ore mining tin ore beneficiation process and tin ore ... Tin Ore Mining, Tin ore beneficiation process and . ... There are both stationary tin ore processing plant and mobile crushing screening plant for your .

Iron Ore Smelting Process Brighthub .

This process prepares it for the next stage which is the heating and forging to the desired wrought iron designs and shapes. This used to be an art of the blacksmith, but is now normally carried out by machines. Steel Process. This process is used to remove impurities from the pig iron produced in a blast furnace.

The Properties, Production and Applications of Tin

Tin is smelted at temperatures of up to 2500°F (1370°C) with carbon to produce low purity tin and CO 2 gas. It is then refined to high purity (>99%) tin metal through boiling, liquation or electrolytic methods. Applications. Many everyday items that we associate with tin, such as "tin cans" and "tinfoil", are actually misnomers.

tin ore to tin metal process .

tin processing | Encyclopedia Britannica. Sep 5, 2013 ... tin processing, preparation of the ore for use in various products. Tin (Sn) is a relatively soft ...

of tin process of ore concentration by dense

Flotation of Tin MineralsHandbook of Flotation . – Flotation of Tin ... scrubbing the ore is practiced before tin concentration. ... as a complementary ...

Tin Ore | Feed The Beast Wiki | FANDOM .

Tin Ore is an ore found commonly in upper layers. It can be smelted into Tin Ingots or turned into two Tin Dust using a Macerator, Pulverizer, or Rock Crusher. In the Pulverizer, it has a 5% chance of also giving one piece of Pulverized Iron.

Gold Smelting Process | Sciencing

Ore Processing. The first step in the gold smelting process occurs when ore containing gold is mined from the earth. At this point, the crude binding matter and the gold metal need to be separated. This is accomplished by pulverizing or crushing the gold ore, and then placing it in a furnace.

Latest Posts

- مطحنة الكرة لإفادة خام الحديد في مصر

- esguarnac michelena mil ve

- تعدين الذهب ومعالجته في السودان

- سعر كسارة الفك النيجيري

- مصنع الصين في العلامة التجارية المعدات الزراعية

- كسارات مستعملة للبيع في المغرب

- محاجر أفريقيا الحمراء في المملكة العربية السعودية

- الشركات المصنعة للمطحنة الدوارة في العراق

- بيع كسارات إعادة التدوير

- بيع كسارة الحجر المتنقلة الصغيرة

- مطاحن كروية للبيع في غوتنغ

- دليل طحن mencari mesari

- سحق وغربلة في الجزائر

- كسارة مخروط مصرى

- المملكة العربية السعودية الحزام الناقل مصنع

- gravel processing machine

- price list of mining equipments in india

- coal fire pulverizer equipment plant

- por le mining plants south africa

- grinding mills craigslist

- coal wash plant yield crusher settings

- gold leaching plant

- heavy stone crusher india

- crusher manufacturers in andhra pradesh

- buy rockdust greece greece

- business plan south africa stone crusher

- small capacity steel slag crushers

- barytes mine in brazil

- crusher and grinding mill for quarry plant in lafayette

- used volumetric mixers